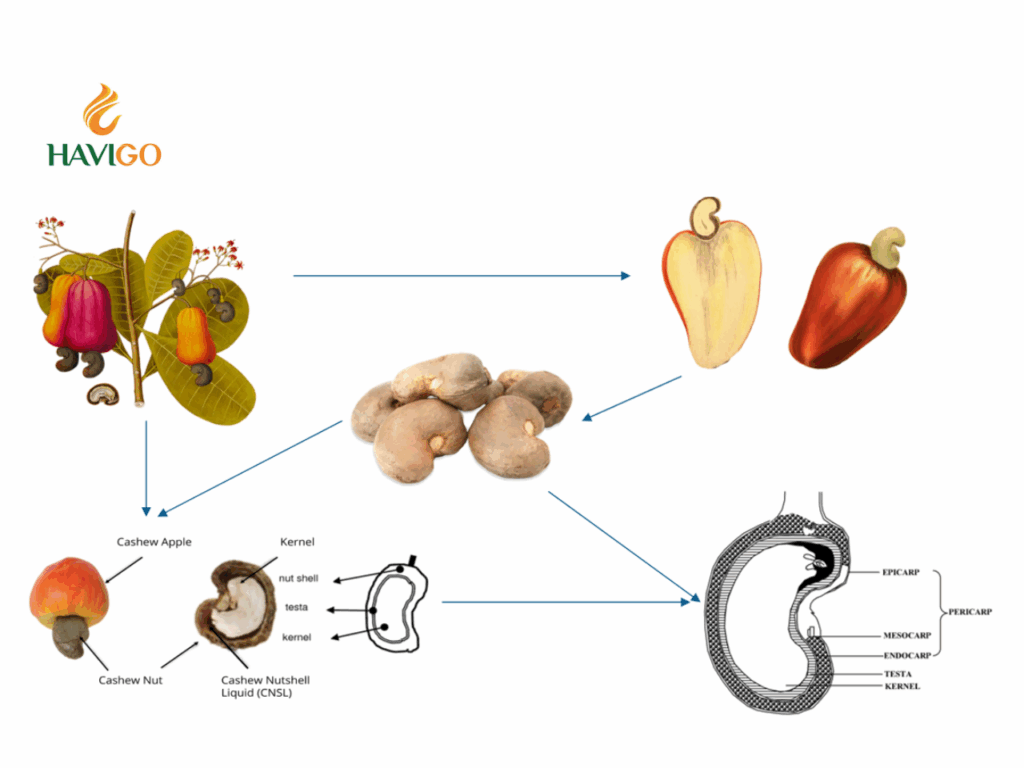

Processing cashew nut – Introduction

Processing cashew nut involves several crucial steps before the final product reaches consumers. Each stage plays a vital role in maintaining taste, texture, and overall safety. Furthermore, processors blend traditional techniques with advanced machinery to enhance efficiency and ensure consistent quality throughout the process.

Harvesting Cashew Apples

First, the process starts in the orchard. Farmers carefully harvest ripe cashew apples by hand to avoid bruising. Immediately after that, they twist the nut off the apple. Notably, only the nut is used for further processing, while the apple may serve other purposes.

Drying the Raw Cashew Nuts

Right after separation, the raw nuts are spread under direct sunlight. This drying step is essential because it reduces moisture and prevents mold. As the nuts dry, their shells harden. Consequently, the next steps become smoother and more effective.

Roasting the Cashew Shells

Following drying, the nuts enter the roasting stage. Roasting helps soften the outer shell, allowing the inner kernel to loosen. Typically, processors choose between steam roasting and drum roasting. Steam offers better results since it preserves kernel quality and avoids oil contamination.

Shelling the Cashew Nuts

Once roasting is complete, the nuts proceed to the shelling stage. Workers or machines crack the shells to retrieve the kernels inside. To avoid breakage, they handle each nut with extreme care. Skilled labor is often essential for better accuracy and minimal damage.

Peeling the Inner Skin

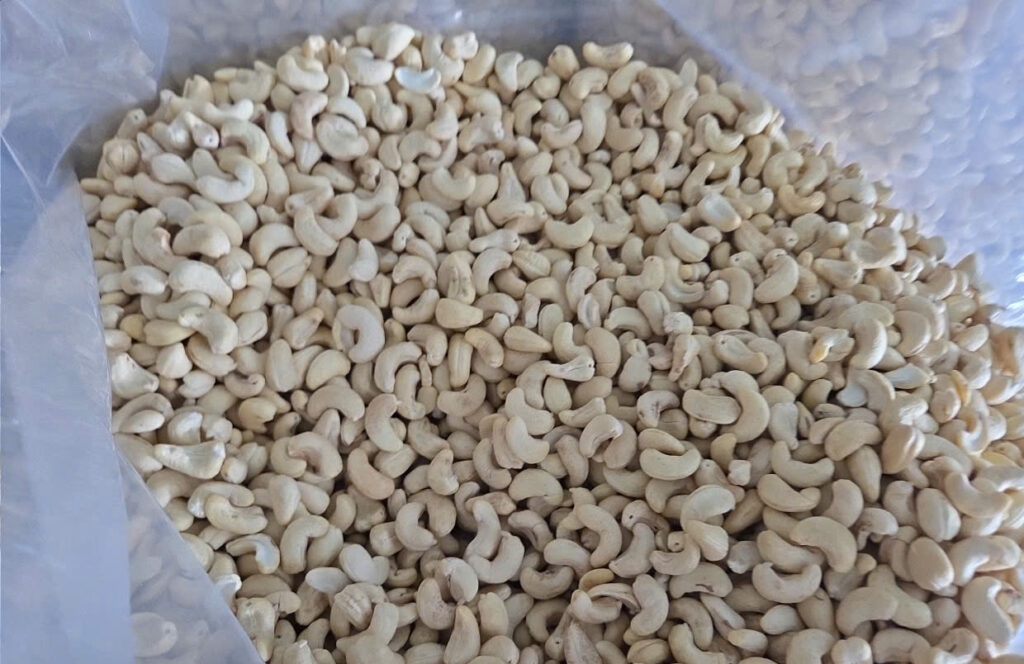

After shelling, the kernels still have a thin brown skin. Workers or machines peel off this layer using either mechanical tools or manual methods. Right after peeling, the process moves to grading. At this point, processors sort the kernels by size, color, and overall quality. This step greatly improves both appearance and market value.

Grading and Sorting the Kernels

Next, the sorted kernels go through grading based on standard classifications. Processors divide them into categories like W180, W210, W240, and W320. These grades indicate how many kernels fit into a pound. Typically, fewer nuts per pound mean larger size and higher market value. Consistent grading ensures uniformity across export and retail shipments.

Quality Inspection and Testing

Before packaging, each batch undergoes a strict inspection. Trained technicians remove defective, broken, or discolored kernels. Furthermore, they test for moisture, aflatoxins, and foreign contaminants. This quality control step ensures every shipment meets international food safety standards.

Vacuum Packing and Sealing after Processing Cashew Nut

Finally, the fresh cashew kernels are ready for packing. Since they are sensitive to air and moisture, airtight packaging is essential. Therefore, processors use vacuum-sealed or nitrogen-flushed bags. This not only preserves freshness but also extends shelf life and prevents spoilage during transit.

Labeling and Export-Ready Packaging

After sealing, the cashew kernels move to the labeling stage. Here, each package receives details like grade, weight, origin, and expiration date. Then, they are packed into cartons and prepared for export. To meet international standards, most producers choose food-safe, eco-friendly packaging.

By-Products from Cashew Processing

Interestingly, cashew processing doesn’t stop at the nut. In addition to kernels, by-products such as cashew nut shell liquid (CNSL) are collected. This liquid finds use in manufacturing lubricants, paints, and brake linings. Moreover, the cashew apple is often turned into juice, jam, or even fermented beverages.

Final Thoughts on Processing Cashew Nut

Cashew nut processing is a precise and multi-step journey. It involves careful handling at every stage to maintain high standards. From field to factory, each phase impacts the nut’s final quality

Stay Connected with Havigo Vietnam

Havigo Company Limited is active in the agricultural export sector, and we aim to bring high-quality Vietnamese agricultural products, including spices, rice, beans, and fruits, to the global market. We supply you with high-quality products at competitive prices.

If you are interested in importing Vietnamese desiccated coconuts, please contact us via WhatsApp: +84 886970996 for excellent support.

We are confident in our ability to consistently deliver in a way that meets the highest quality standards while offering competitive pricing within the market.

For more information about our products, please visit our LinkedIn